A heat press in a lot of ways is like a car. It can be an extremely useful tool, but to keep it running smoothly you need to perform regular maintenance. So in order to avoid any downtime or costly repairs, here are 3 essential areas of maintenance to keep your heat press running smoothly.

1. Keep The Upper Platen Clean

The upper platen is quite possibly the most important part of your heat press. And keeping it clean is the best way to extend it’s life and keep it running like new. The easiest way to do this is to prevent anything from sticking to it in the first place. This can be done using cover sheets like Kraft Paper, Teflon Sheets, or an Upper Platen Protector while using the heat press.

But if you do happen to get something stuck to it, cleaning sooner than later will save you a lot of headache. Grab an old rag or t-shirt and with the press still hot try to scrub the ink or vinyl off (be careful not to burn your hands). If scrubbing with a dry rag doesn’t work, purchase some non-abrasive iron cleaner (safe to use on teflon) from your local supermarket. Follow the instructions for that product and that should help you scrub off whatever is stuck.

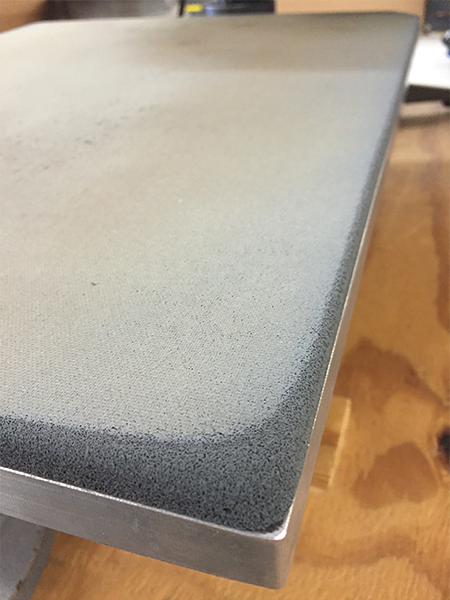

2. Maintain Lower Platen Rubber Pad

The lower platen rubber pad is a part of your heat press that gets a lot of use and therefore can wear down over time. As it wears down it can cause uneven pressure, which will negatively affect your heat transfers. And again this is another item that is easier to maintain than repair. Keeping it clean is important, and a good way to do this is to cover it with a Teflon Lower Pad Protector. This cover makes it easy to clean (with just a single swipe of a rag) but also protects the edges and corners from getting worn down. It also makes it easier to slide your garments on and off.

But if you don’t have a lower pad protector, and your lower pad edges are rounded and worn down, keep your transfers away from the edges when pressing. If the sides and corners of the rubber pad are lifting up off the metal, go to your local hardware or automotive parts store and purchase some high temperature adhesive. Use that to glue the rubber pad back down onto the metal base.

Note: If you own a Hotronix heat press and your lower rubber pad is in very poor condition, you can order a replacement pad or lower platen from Hotronix.com.

3. Greasing the joints

This is often an overlooked part of maintaining a heat press. In fact some manufacturers claim you don’t need to grease anything. And this may be true when the machine is brand new. But over time and through use, friction will start to wear down those moving joints. So here’s what you can do.

Depending on use, check and grease all moving joints with some high temp grease (typically found at most hardware/automotive stores). This includes the pressure adjustment spindle. Do this at least once a year, more often if you use the press frequently. And remember, a little grease goes a long way, so don’t overdo it. If too much grease builds up on those joints you risk getting your garment greasy while pressing. So be sure to wipe away any old or excess grease before using the machine.

While we can’t cover every area of heat press maintenance, there are many more ways you can keep your heat press in good working condition. Check back regularly for new/updated articles. And of course, always follow the manufacturers instructions regarding power requirements, operation conditions, etc…

For more info or if you have any questions, call or email our heat press professionals:

1-800-234-4890 or support@wellingtonhouse.com

If you’re in the market for a new heat press, check out Wellington House’s Heat